Background

The end customer is one of the world's best-known producers of pumps and valves. The USA represents a large part of their market, which means that the products must fulfil a number of American legal requirements, including fire safety, where the Underwriter Laboratories (UL) is the responsible institution that determines the requirement profile.

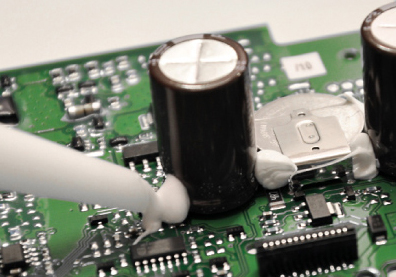

Silicone mission

Components in a control unit must be protected with a viscous silicone which, due to US requirements, must be approved for fire-retardant properties according to the UL94 test. The silicone must not jeopardise the electronics and must be able to cure at room temperature. It would be easy to manufacture: no two components could be considered.

Tribotec's solution

Encapsulate components with RTV160 - a viscous one-component electronics silicone, approved to UL94 standards. RTV160 emits small amounts of methanol as it cures, which does not affect the electronics at all. RTV160 is applied directly from the cartridge in small dabs around the components and allowed to cure using humidity. It has no odour and is otherwise a very friendly product from a work environment point of view.