A common question we get asked when it comes to adhesives is how to bond oily or difficult plastics in a sustainable way? It can be a challenge that's hard to crack, but we have some clever solutions for joining hard-to-glue plastics and rubbers as well as metals.

Fatty plastics are more difficult to bond because they have a relatively low surface tension. Therefore, to make surfaces of oily plastics and other materials such as rubber and metal stick together, you need to use an adhesive with a lower surface tension than the oily plastic material.

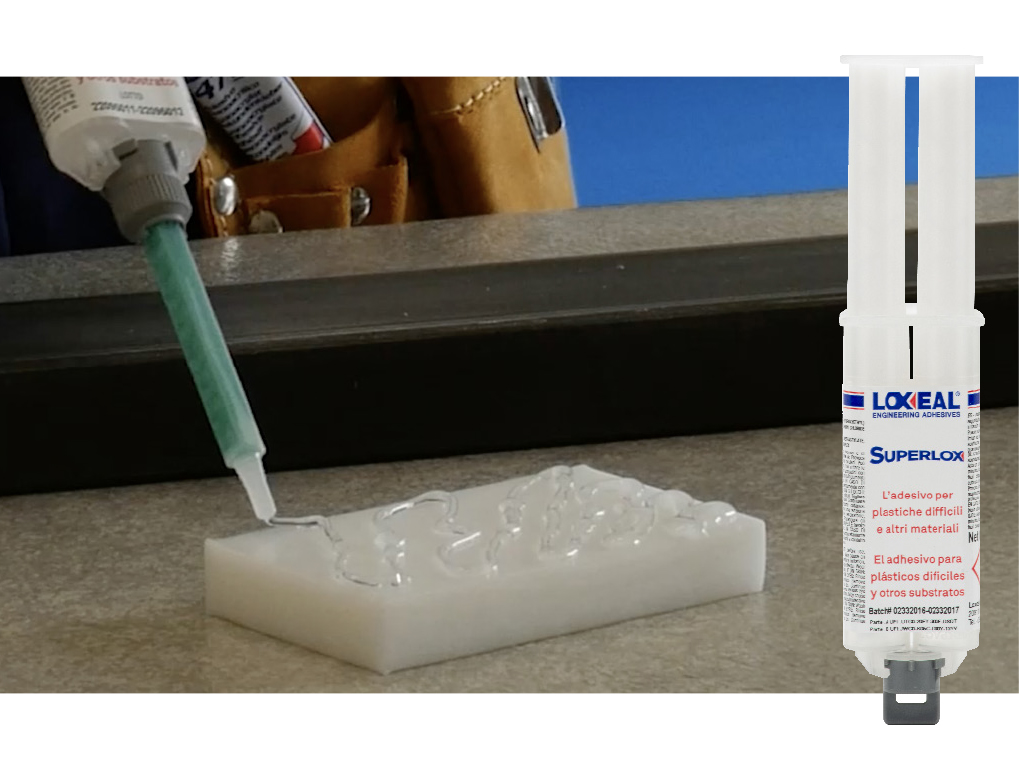

We recommend Loxeal Superlox which is a two-component fast-setting acrylic adhesive, designed to bond a wide variety of materials, even in combination with each other. Ideal for difficult to bond materials and easy to use.

Loxeal Superlox:

✓ Allows you to create a glue joint with extremely

small gap.

✓ Easy to use, 2-cartridge mixer tube.

✓ Provides a transparent adhesive joint with high shear and peel strength.

✓ Ideal for plastics such as PP, PT, PTFE and PMMA, rubber, metals, wood and leather.

✓ Requires no preparatory surface treatment.

✓ Fixation time: 10 minutes.

If you have any questions about which adhesives are suitable for your project, you are always welcome to contact us!